| As New

Age of Growth for Nuclear Technology Opens:

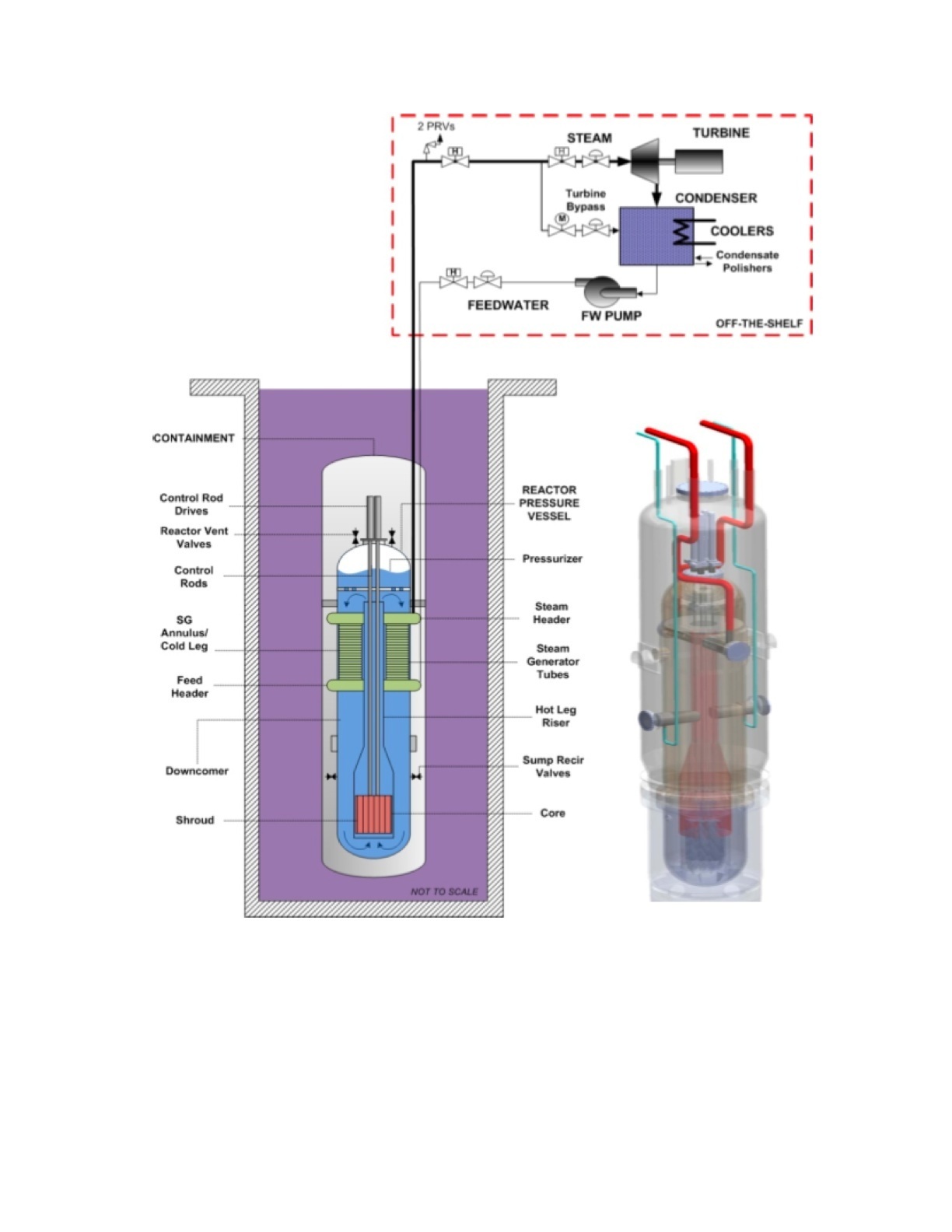

Asia starts to study the benefits of Scaling Down Last year Forbes Magazine's

"Companies to Watch" column cited a U.S., Oregon-based company, NuScale

Power, Inc., as a company to watch. NuScale’s new technology aims

to make "a scaled-down light water nuclear reactor designed to be more

affordable, safer and scalable for small, limited or growing energy

markets". Why is this technology so important today? In the

U.S., more than 104 nuclear power plants successfully generate about

20% of the electricity for the country. However, to maintain that

percentage over the next 30 years, it is predicted that the industry

will need to build another 50 reactors. One current issue is that

conventional nuclear reactor sizes are large and finding the financing

to build them is quite difficult. NuScale's new technology offers a

natural circulation light water reactor that fits into a 60 x 15-foot

cylinder. The whole nuclear reactor system can be prefabricated

and shipped to a power plant site by rail, truck or barge. Its modular

design means small energy providers can install a single NuScale

reactor; then scale up by adding more modules as demand increases.

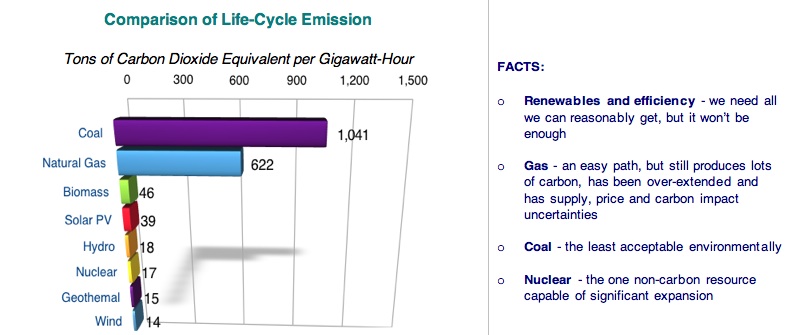

Not only in the U.S. will this technology be useful. It has potential to help countries in Asia and elsewhere: from smaller countries like perhaps Cambodia, to larger countries like Vietnam or Thailand who are overly-dependent on natural gas or coal both of which produce CO2, a greenhouse gas. It is also needed within these countries where communities like industrial parks or industrial zones need cheaper, dependable power or for islands like Phuket or Koh Samui in Thailand; to the small countries that currently rely on mid-range utilities and either don't have oil, hydro or other resources.  In addition to reducing the size of the reactor, the new technology offers a natural circulation design that produces power with a greatly simplified system. It helps reduce maintenance costs and improves safety, including resistance to earthquakes. Each of the nuclear power plant modules will produce 40,000 kilowatts (40 MegaWatts) of electricity. With its scalable design, it allows facility owners to co-locate multiple modules within a single power plant - adding capacity as it is required up to as much as 1,000 MegaWatts at one facility. This "scalability" is important as it allows a nation to diversify its energy generation so that if one power plant fails or needs to be taken off-line for maintenance or refueling the remainder of the grid can more easily support the one unit off-line. The NuScale Power system operates at temperatures and pressures that are familiar in the industry, uses fuel that can be manufactured on the same lines as conventional reactor fuel, and uses conventional pressure vessel technology that is small enough to be produced in a number of qualified factories. One key feature of this small reactor is that it will be completely assembled in a factory and shipped to the site ready for installation - another important factor in a developing country environment. The design of the NuScale plant is based on decades of operating experience with light water reactor technology. Water acts as the primary coolant within the reactor system. Water is also turned into steam within the steam generators to turn the turbine generator that makes electricity. NuScale fuel is similar to the fuel used in current operating nuclear plants except that NuScale fuel assemblies are 2 meters long instead of 4 meters. Each assembly contains 17 rows and each row holds 17 fuel rods.

The NuScale design incorporates a low profile reactor building, submerged containment, and impact shields that provide a hardened target against external threats.

For more information: please visit www.NuScalePower.com Picture below: NuScale nuclear power plants operate on the principle of natural circulation. In this convection process, water is heated by the nuclear fuel, rises within an internal chamber until it is drawn out and passes over steam generators. The reactor water loses its heat when it turns water in the steam generators into steam to power the turbine generator and make electricity. Each integrated NuScale containment vessel and reactor measures 18 meters in length by 4 meters in diameter and weighs 270 metric tones. |